The Evolution of Precision:

Helical Blade NC Cutters in Modern Manufacturing

In the fast-paced and exacting activity of packaging and manufacturing, the quest for precision and efficiency is relentless. With businesses continually expanding and evolving, the need for equipment that can keep pace with the growing demands is critical. Enter the Helical Blade NC (Numerical Control) Cutter, a marvel of modern engineering that promises to revolutionize the way we think about industrial cutting processes.

The Cutting Edge of Technology

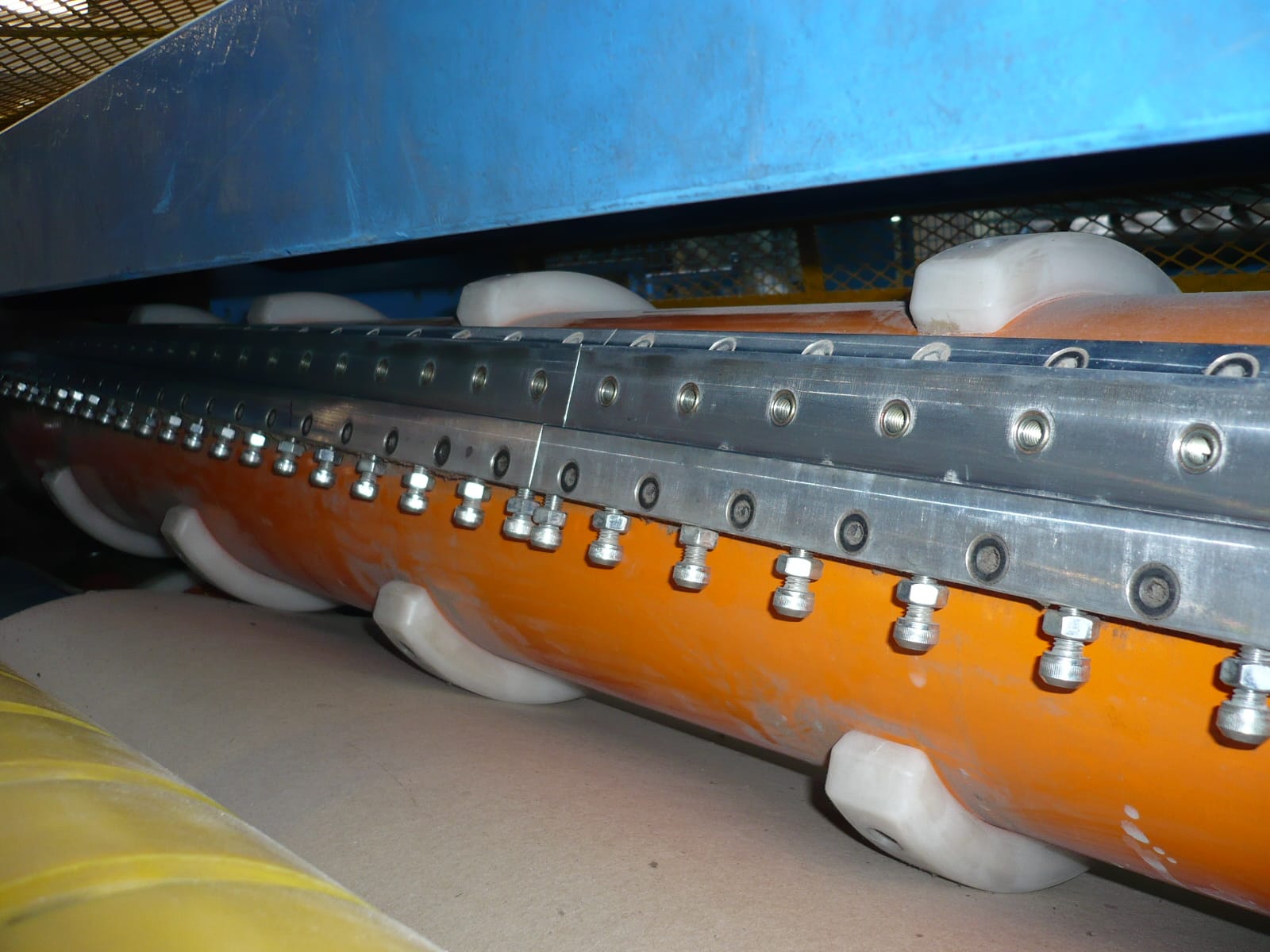

Helical Blade NC Cutters stand at the forefront of innovation, offering unparalleled accuracy in the cutting of corrugated cardboard—a staple material in the packaging industry. These cutters are meticulously designed to address the stringent requirements of contemporary production lines, ensuring that each cut is executed with the utmost precision.

Key Features

What sets Helical Blade NC Cutters apart is their array of features tailored to enhance productivity and performance. These include:

-High-Speed Operation: Time is of the essence in manufacturing, and these cutters are built to operate at high speeds without compromising on accuracy.

-Advanced Control Systems: Equipped with sophisticated NC systems, these machines allow for precise adjustments and control, enabling operators to achieve the desired outcomes with minimal waste.

-Durability: Crafted with robust materials, Helical Blade NC Cutters are designed to withstand the rigors of continuous operation, reducing downtime and maintenance costs.

Customisation Options

Understanding that no two manufacturing processes are identical, Helical Blade NC Cutters offer a range of customisation options. Businesses can select from various blade sizes, control systems, and additional features to ensure that their cutter is perfectly suited to their specific needs.

Advantages Over Traditional Cutting Methods

The adoption of a Helical Blade NC Cutter brings with it a host of advantages:

– Enhanced Precision: The helical design of the blade ensures a cleaner, more consistent cut, which is vital for high-quality packaging.

– Reduced Material Waste: With greater accuracy comes reduced waste, as materials are utilized more efficiently, leading to cost savings and environmental benefits.

– Improved Safety: Automated controls and safety features minimize the risk of operator injury, a significant concern in any industrial setting.

A Smart Investment for the Future

For engineers and directors contemplating the acquisition of a new Helical Blade NC Cutter, the decision is not merely about purchasing a piece of equipment; it’s an investment in the future of their business. By embracing these advanced machines, companies can expect to see a tangible improvement in their production capabilities, positioning themselves as leaders in a competitive market.

Conclusion

The integration of Helical Blade NC Cutters into manufacturing processes is more than just an upgrade—it’s a transformative step towards achieving operational excellence. With their superior precision, efficiency, and customisation options, these cutters are not just meeting the needs of modern production—they’re setting new standards for the industry at large. For businesses looking to stay ahead of the curve, the Helical Blade NC Cutter is an indispensable tool in the arsenal of innovation

CNC Cutters are the Cutting-Edge Technology

Industrial Engineers We Can Make a Difference?

–