We carry out service and repairs to machinery in minimum time for many of our clients. When you have a machine breakdown that can happen at truly short notice, we do our utmost to get your machinery running again. Sometimes by working with up-to-date innovative methods where possible, to keep the customer’s corrugator machinery running.

Service

However, the situation may allow for the repair to be manufactured offsite, while the production machinery may not work or run at full speed in this mode until the component repair is completed.

This means that, if possible, the production line is kept running, which is often preferred. Then to having the line stopped altogether, during the time for the service & repairs being organised and carried out.

In this situation, innovation management includes a set of tools that allow managers plus machine operators to cooperate with a mutual understanding of the processes and goals.

On other occasions, this may not be possible, and the hard truth of the matter is that the machinery will need to be stopped for the repair to be carried out.

This is a good example of where an audit, of the historical records for the machine in question, may be helpful to put light on reoccurring problems in their initial stages of development.

This process can be viewed as an evolutionary integration of a company’s management and engineering technology being implemented for the greater good of the company.

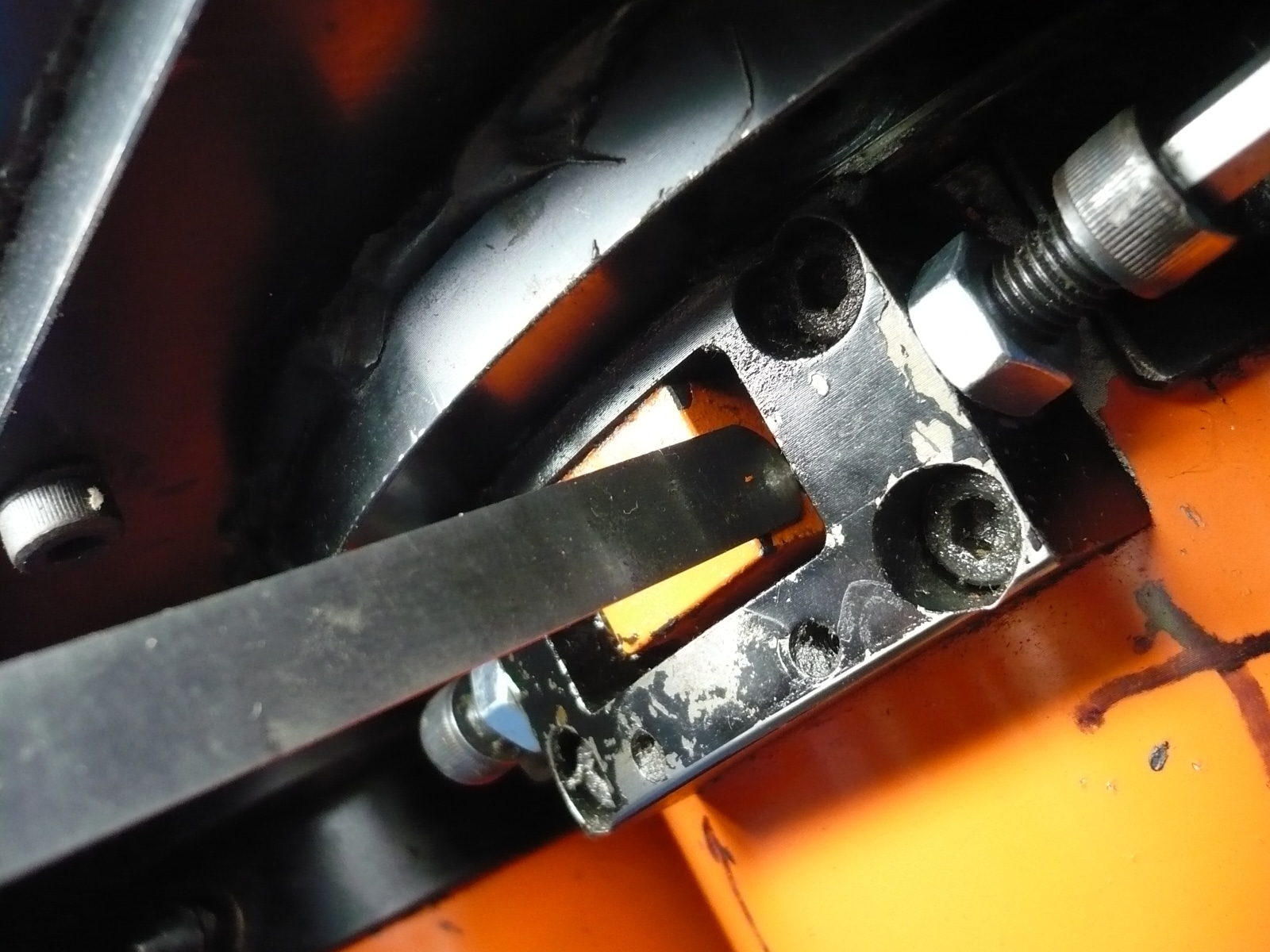

NC Cutter Helical Blade Adjustment

This is a delicate process that many will not take on without training or tutoring from an experienced person in this type of knife. This is a slow and tedious task that just takes time & patience to accomplish. The challenge is to take your time, as the closer you get to the final settings you must exercise great care and attention to detail.

This is a delicate process that many will not take on without training or tutoring from an experienced person in this type of knife. This is a slow and tedious task that just takes time & patience to accomplish. The challenge is to take your time, as the closer you get to the final settings you must exercise great care and attention to detail.

Unlike many older types of cut-off knives, they are unforgiving if over-adjusted and this can turn into a very costly event. Not to mention the loss of production time on your NC Cutter which can be mounted in a sheeter, laminator, or corrugator.

Modular Form

This NC Cutter is manufactured in modular form, therefore making it quite easy to work on during a service. Should you ever need to work on the knife bars for some reason that you could not do in its assembled position.

The centre knife bars can be easily removed by sliding them out as one section. This allows you to remove the end frames to inspect the gears, bearings or replace the oil seals if required, after many years of productive service.

Monitoring process

Thus, you can utilise engineering crews to always be aiming to be proactive as much as possible as the monitoring process is always active.

Thus, you can utilise engineering crews to always be aiming to be proactive as much as possible as the monitoring process is always active.

As opposed to being forced into reactive situations that may lead to dire consequences and loss of production time.

By investigating & conducting, an analysis of past performance records, which can be viewed on a regular basis. Using up-to-date monitoring techniques, many repairs on modern machinery can be reduced or avoided.

The useful information gained from the monitoring process can help an experienced person in this type of machinery, make recommendations for actions to be carried out as required. Any part or bearing not preforming at its best-known condition can be replaced as early as conveniently possible. Thereby minimising lower product quality and slower running production speeds. Avoiding costly breakdowns or service occurring during long and busy periods of production.

As a result, many machinery downtimes are reduced! Parts that have an expected lifetime, can be replaced in a planned and efficient manner. The overall result is that these machines are kept running at maximum productivity over exceedingly long operating times.

Service and Repairs Priority

But when a major breakdown arrives and key machinery is stopped for several days or longer, through the shortage of spares that are not available but have to be made immediately!

Heads are turned and thoughts of getting adequate spares become so fundamental to the overall economic viability of the production operation.

The company must decide to reduce these occurrences to a minimum.

Hopefully by having the engineering and production staff involved in drawing up the priorities as seen by them as they are the people “at the coal face” and can easily assess what is needed in scale & quantity.

Then it’s up to the company team as to the time scale that spares are built up, to future-proof production operations, and to maintain greater productivity over the long term.

.